Composition

The workshop is 121 square meters in size and is divided into four main zones. In addition to the main zone where overhauls are performed, there is an independent cleaning zone, a polishing zone, and a management zone.

Main

The workbench layout faces a large window. The environment is with bright and full of light. The facility is equipped with a full range of brand service center standard equipment, including an air vacuum system, various measuring instruments, waterproof testers, UV lamps, magnetic de-magnetizers, and winding machines.

Cleaning

This is an independent space equipped with a Japanese-made ultrasonic rotary cleaning machine. Waste liquids used in steam cleaning, drying, and cleaning are disposed of in accordance with the Japanese law.

Polish

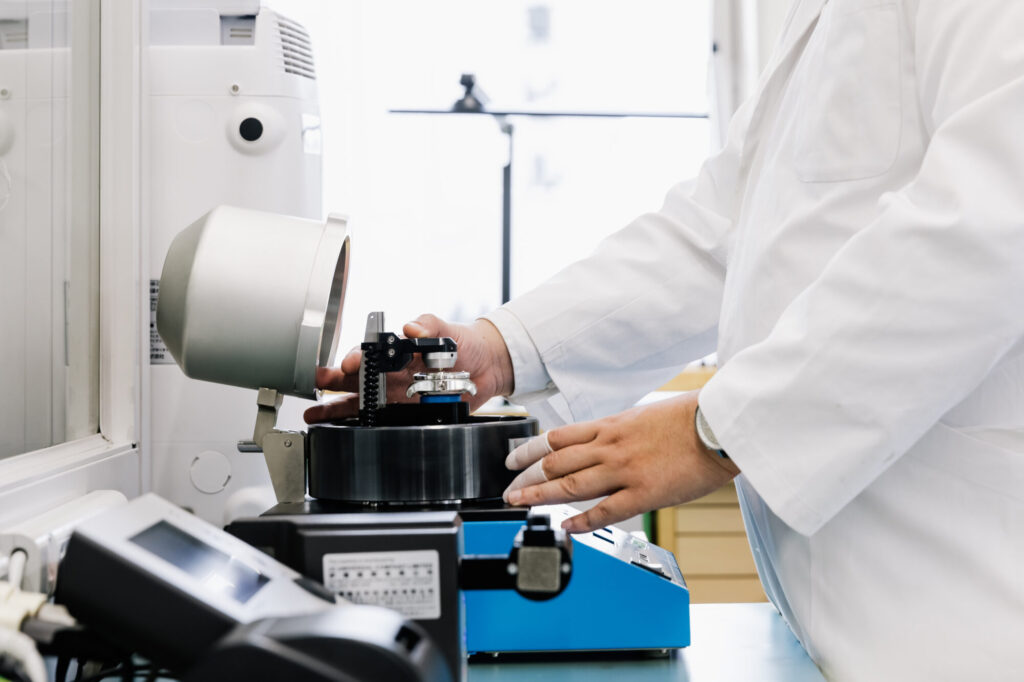

Dedicated space with ventilation and air conditioning. Equipped with a variety of specialized fixtures and attachments for implementing brand-specified finishes.

The space is independent of noise and dust impact, yet does not feel isolated because it is partitioned with a large glass wall.

Administration

All watches received are inspected here and registered into the system. The ordering of parts is done brand by brand using each system.

A dedicated watch-repair management tool called SAVinsight is used to determine is used to check the workshop’s performance on a daily basis. The customer’s watches are stored in the vault.

And they are shipped safely using the company’s customized packing boxes.

Partnership

Global & independent service center network